In the cosmetics industry, laboratory testing is indispensable for ensuring product safety, efficacy, and quality. This rigorous process involves various specialized tests and advanced equipment to verify that products meet high standards. Here, we explore the critical types of laboratory testing and the sophisticated instruments used.

The Role of Laboratory Testing in Cosmetic Industries

Laboratory testing is a comprehensive approach that encompasses several types of evaluations. These tests ensure that cosmetic products are safe for consumers, perform as promised, and maintain their quality throughout their shelf life. The process often involves a combination of analytical laboratory services and specific equipment to achieve accurate results.

1. Ensuring Safety in Cosmetic Products

Safety is a top priority for any cosmetic product. Laboratory testing provides a comprehensive assessment to ensure that products are safe for consumer use. One crucial aspect of safety testing is patch testing, which evaluates the potential for allergic reactions or skin sensitivities. This is followed by dermatological testing to observe the product’s effect on the skin under professional supervision.

2. Ensuring Compliance in Malaysia

Compliance with regulations is another significant reason for conducting laboratory tests. Malaysia have stringent regulations governing cosmetic products, and laboratory testing help companies adhere to these requirements. This involves regulatory testing, which ensures that products meet local and international standards, thus avoiding legal issues.

3. Evaluating Efficacy and Quality

Laboratory testing is also instrumental in verifying the efficacy of cosmetic products. Clinical trials are conducted to test a product’s effectiveness in real-world conditions, confirming whether it delivers on its claims, such as anti-aging or moisturizing properties. Consumer testing provides valuable feedback on the product’s performance and overall satisfaction, helping brands make informed improvements.

Advanced Analytical Techniques for Laboratory Testing

To support the safety, efficacy, stability and microbiological tests, sophisticated analytical laboratory services and equipment are used:

Ion Chromatography

This ion chromatography technique analyzes the composition of ingredients and identifies impurities by separating ions and polar molecules. It is essential for ensuring the purity of cosmetic products.

Thermal Desorber

Used to analyze volatile compounds in a sample, this instrument helps identify any unwanted substances that could affect product safety or performance. Get more info here.

Particle Size Analysis

Utilizing a particle size distribution analyzer, this test measures the size of particles within the product. Consistent particle size is crucial for maintaining the stability and effectiveness of the product.

Zeta Potential Analyzer

The zeta potential analyzer Measures the charge on particles in a colloidal system to assess stability. This analysis helps ensure that the product remains stable over time.

Contact Angle Analyzer

The contact angle analyzer evaluates the wettability and adhesion properties of materials. This information is valuable for understanding how the product interacts with surfaces and its application properties.

Equipment for Laboratory Testing

Effective laboratory testing requires specialized equipment to ensure accuracy and reliability:

Glassware Washers

Essential for cleaning laboratory glassware, glassware washers ensure that all equipment is free from contaminants before use.

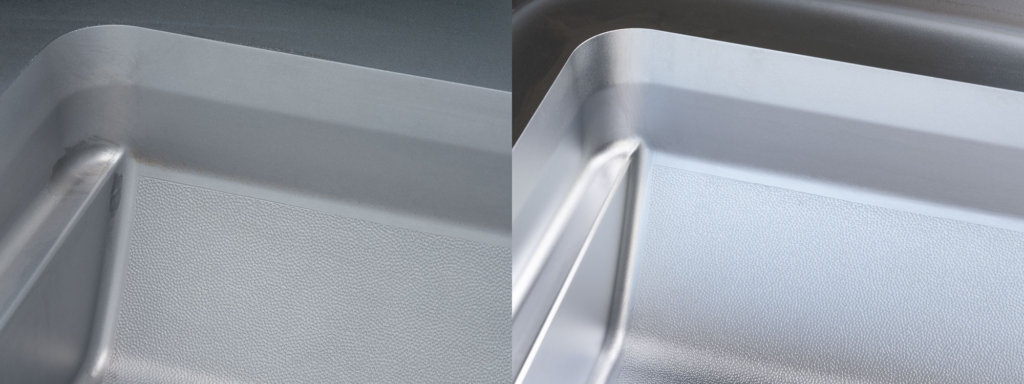

Laboratory Washing Machines

Similar to glassware washers, these laboratory washing machines clean and disinfect a variety of laboratory instruments, maintaining the integrity of testing processes.

BET Analysis

This BET analysis measures the surface area of materials using nitrogen adsorption, providing insights into the texture and porosity of the product’s ingredients.

Advanced Laboratory Testing Ensures Cosmetic Excellence

Laboratory testing is a cornerstone of the cosmetics industry, involving a range of tests and sophisticated instruments to ensure product safety, efficacy, and quality. Advanced techniques like thermal desorber, zeta potential analysis, particle size analysis, and contact angle analysis play crucial roles in this process.

By utilizing these methods and maintaining high standards with equipment such as laboratory washing machines, cosmetic companies can deliver products that meet rigorous safety and performance criteria. Find out more here!